DMR-QA: Analysis Tips

Useful Tips to Improve Your Analysis Techniques

To assist you with various tests and analyses you may be conducting for DMR-QA, Waters ERA’s technical experts have put together the following useful tips, which may improve your analysis techniques and help to ensure your success.

JUMP TO: Biochemical Oxygen Demand | pH | Total Suspended Solids | Oil and Grease | Coliforms

Biochemical Oxygen Demand (BOD)

Waters ERA fields many questions regarding BOD analysis, because it has numerous steps and requires some attention to detail. Very simply, the purpose of the test is to determine the amount of dissolved oxygen used by microorganisms to break down the organic matter in a sample. As microorganisms and larger aquatic species both rely on the dissolved oxygen in any water system, maintaining tight control over BOD is necessary to having a balanced ecosystem.

As contamination, either from residual chlorine or organic material, can drastically affect your results, it is critical that every piece of glassware and other apparatus used in your analysis is scrupulously clean. All of your test equipment should be well cleaned after each use and then rinsed at least three times with deionized or otherwise purified water prior to being used again. Disposable BOD bottles and other apparatus have helped to lessen the possibility of carryover, but it is important to store and handle these items per the manufacturer’s recommendations. Analyzing seeded and unseeded water blanks will help you determine if you have any contamination in your process.

Equally important, but often overlooked, is the requirement to adjust the pH of samples prior to dilution. This step is important because the test must be conducted at a pH between 6.5 and 7.5 in order for the results to be accurate. In some municipal labs, adjusting the pH of “real” samples is never required as they always fall in the required range. Over time, some of these labs even begin to stop checking the pH of their samples altogether. While this may not cause a problem when testing plant effluents, it can be a significant problem when analyzing a DMR-QA sample. In order to prepare a homogenous, stable proficiency testing sample, Waters ERA preserves the Demand concentrate with acid. Once you have made the initial dilution into deionized water, the sample pH will still be slightly acidic. If you do not adjust the pH of this sample prior to preparing your analytical dilutions, you run a high risk of failing the sample. The best way to adjust the pH is to use a dilute solution of sodium hydroxide (~0.2 molar) and add it one drop at a time to the diluted sample, mixing and then checking the pH after each addition until the pH is between 6.5 and 7.5.

As contamination, either from residual chlorine or organic material, can drastically affect your results, it is critical that every piece of glassware and other apparatus used in your analysis is scrupulously clean. All of your test equipment should be well cleaned after each use and then rinsed at least three times with deionized or otherwise purified water prior to being used again. Disposable BOD bottles and other apparatus have helped to lessen the possibility of carryover, but it is important to store and handle these items per the manufacturer’s recommendations. Analyzing seeded and unseeded water blanks will help you determine if you have any contamination in your process.

Equally important, but often overlooked, is the requirement to adjust the pH of samples prior to dilution. This step is important because the test must be conducted at a pH between 6.5 and 7.5 in order for the results to be accurate. In some municipal labs, adjusting the pH of “real” samples is never required as they always fall in the required range. Over time, some of these labs even begin to stop checking the pH of their samples altogether. While this may not cause a problem when testing plant effluents, it can be a significant problem when analyzing a DMR-QA sample. In order to prepare a homogenous, stable proficiency testing sample, Waters ERA preserves the Demand concentrate with acid. Once you have made the initial dilution into deionized water, the sample pH will still be slightly acidic. If you do not adjust the pH of this sample prior to preparing your analytical dilutions, you run a high risk of failing the sample. The best way to adjust the pH is to use a dilute solution of sodium hydroxide (~0.2 molar) and add it one drop at a time to the diluted sample, mixing and then checking the pH after each addition until the pH is between 6.5 and 7.5.

Here are a few additional keys to improving your BOD analyses:

- Make sure that your incubator temperature remains consistent at 20±1°C.

- The use of an independent thermometer is highly recommended.

- When analyzing CBOD be cautious about using plant influent as your seed if it contains a high percentage of nitrifying bacteria. The nitrification inhibitor you add to the sample will suppress the nitrifying bacteria and you may not be left with enough carbonaceous bacteria to generate proper oxygen depletion.

pH

While pH is generally considered a simple analysis, it requires some attention to detail to ensure consistently accurate results.

It is always better to run calibration, check and field samples at room temperature rather than relying on automatic temperature compensation (ATC). If you must analyze samples of different temperatures, make sure that your meter has ATC and that it is properly working.

Use fresh, high-quality calibration buffers, such as Waters ERA's pH calibration standards. Never stick the probe into the bottle of buffer or return buffer to the bottle after it has been used once. By following the storage recommendations given by the supplier and making sure to not contaminate the solution, you should be able to use the buffer up until its expiration date.

Using an independent quality control sample will help you identify bad buffer solutions or a probe or meter that is not operating correctly. Finally, you should always bracket the concentration of your real samples with your calibration buffers. By screening unknown samples before analysis, you can identify which buffers to use.

It is always better to run calibration, check and field samples at room temperature rather than relying on automatic temperature compensation (ATC). If you must analyze samples of different temperatures, make sure that your meter has ATC and that it is properly working.

Use fresh, high-quality calibration buffers, such as Waters ERA's pH calibration standards. Never stick the probe into the bottle of buffer or return buffer to the bottle after it has been used once. By following the storage recommendations given by the supplier and making sure to not contaminate the solution, you should be able to use the buffer up until its expiration date.

Using an independent quality control sample will help you identify bad buffer solutions or a probe or meter that is not operating correctly. Finally, you should always bracket the concentration of your real samples with your calibration buffers. By screening unknown samples before analysis, you can identify which buffers to use.

Total Residual Chlorine

Residual chlorine analysis can easily be compromised due to contamination from chlorine present in tap water as well as the volatility of the analyte. A few simple steps can minimize these and other sources of error in this test.

- Make sure all glassware is cleaned and rinsed at least three times with deionized water prior to use.

- Analyze a blank to ensure no contamination from water or glassware is present.

- Samples should be analyzed as soon as possible. Proficiency testing (PT) and certified reference material (CRM) samples should be freshly diluted just before they are to be analyzed.

- Make sure you are using fresh reagents. Reagent packets (powder pillows) generally work very well, but you must make sure that the concentration range of the powder pillow is appropriate for the sample you are testing.

- When diluting PT or CRM samples, some glass pipets may not fit into the neck of the glass ampule. A good solution is to use a clean, gas-tight syringe capable of delivering 1 mL of concentrate.

Total Suspended Solids (TSS)

TSS is a fairly straight-forward test that many laboratories perform. To ensure this analysis is in control:

- Filter an amount of sample to ensure that the resulting residue on your filter is large enough to be weighed accurately yet small enough to dry efficiently. A range of 10-200 mg of residue is recommended.

- Always use a 4-place analytical balance when weighing your filters before and after use.

- Always filter a blank (deionized water) sample and perform corrective action if the results are outside of your normal observations.

- Ensure that your pans and filter papers are completely dry before use. They should be stored in a desiccator after they are dried and before they are used.

- Dry and weigh each sample at least twice to ensure that the filters are completely dry.

- Dried pans and filters should be allowed to cool in a desiccator prior to weighing.

Oil and Grease

Oil and Grease is a gravimetric analysis with some similarities to TSS. A few of the same tips and some unique steps apply to this analysis. As with TSS, it is important to use a 4-place analytical balance for every weighing. Unlike TSS, where you choose the sample size to filter, the entire oil and grease sample should always be used to ensure that all of the analyte is captured. You also need to rinse the bottle and cap three times with solvent to ensure that none of the sample remains attached to the container.

Drying and weighing at least twice should be performed for the oil and grease analysis as well, so that you can make sure the sample is completely dry. It is also necessary to ensure that no water ends up in your collection pans as the dissolved solids present can result in a high bias.

Drying and weighing at least twice should be performed for the oil and grease analysis as well, so that you can make sure the sample is completely dry. It is also necessary to ensure that no water ends up in your collection pans as the dissolved solids present can result in a high bias.

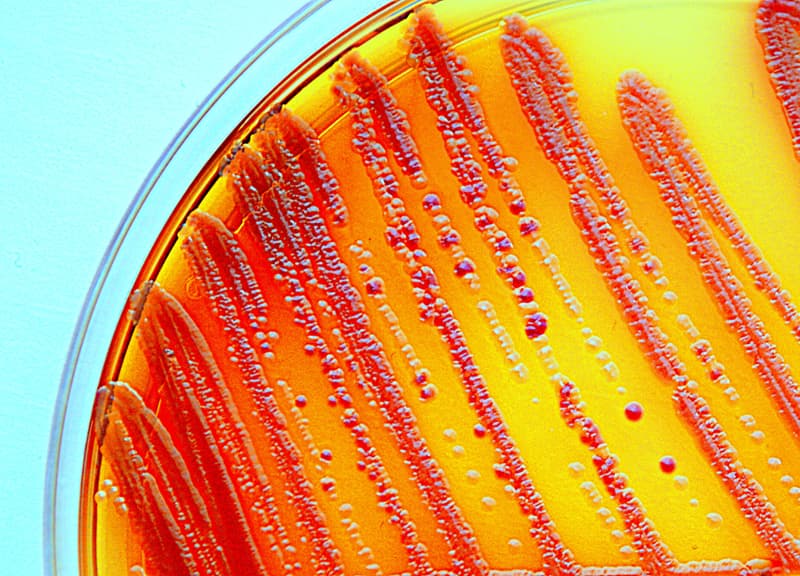

Coliforms

Like BOD, there are many variables that go into an accurate analysis of coliforms. Over the years, Waters ERA has answered hundreds of questions about this analysis with many of the questions focusing on some of the same topics.

Positive Controls: For each new batch of media and method apparatus, test a positive control to demonstrate that the media produces the expected reaction to the organism under test. Reference cultures used for positive controls should come from a national collection, organization, or manufacturer recognized by an accrediting authority. These cultures may be a single-use preparation or cultures maintained by procedures that ensure the continued purity and viability of the organism.

Positive Controls: For each new batch of media and method apparatus, test a positive control to demonstrate that the media produces the expected reaction to the organism under test. Reference cultures used for positive controls should come from a national collection, organization, or manufacturer recognized by an accrediting authority. These cultures may be a single-use preparation or cultures maintained by procedures that ensure the continued purity and viability of the organism.

Negative Controls: For each new batch of media and method apparatus, test a negative control to demonstrate that the media does not demonstrate a false-positive reaction. Reference cultures used for negative controls should come from a national collection, organization, or manufacturer recognized by an accrediting authority. These cultures may be a single-use preparation or cultures maintained by procedures that ensure the continued purity and viability of the organism.

Method Evaluation: All methods in use in the laboratory should be evaluated for their ability to produce acceptable results prior to first use. For quantitative microbiology methods this can be accomplished by participation in an approved proficiency testing program or the analysis of a quality control sample.

Hydration of Pellet: The initial hydration of the gelatin tablet supplied with ERA samples should be performed following the instructions provided. Please do not deviate from the instructions as the certified values and acceptance intervals are based on customer data and deviations could result in an incorrect result. Once hydration of the pellet is complete, perform your analysis immediately. Waiting more than 30 minutes to perform your analysis could have an effect on results. Gently shake the sample prior to taking aliquots for analysis.

Culture Media: Quality of culture media is critical. Never prepare media from raw ingredients if a source of dehydrated media is available. If preparing dehydrated media, follow instructions closely. Always check pH and make any adjustments that are necessary. Always evaluate media prior to first use. Never use media outside of its expiration date and never use media that has not been stored according to the manufacturer’s specifications. Confirm that prepared media and dehydrated media ingredients and proportions match the specifications for your method.

Dilution and Rinse Water: Only hydrate the gelatin tablet using the phosphate buffer supplied by Waters ERA. To perform dilutions and apparatus rinsing, do not use deionized water or distilled water. Waters ERA recommends phosphate buffer or peptone water as it is not uncommon for deionized water or distilled water to cause inhibitory effects. See Standard Methods 9050C 20th Edition for the preparation of buffered water or peptone water.

Order DMR-QA Products

Method Evaluation: All methods in use in the laboratory should be evaluated for their ability to produce acceptable results prior to first use. For quantitative microbiology methods this can be accomplished by participation in an approved proficiency testing program or the analysis of a quality control sample.

Hydration of Pellet: The initial hydration of the gelatin tablet supplied with ERA samples should be performed following the instructions provided. Please do not deviate from the instructions as the certified values and acceptance intervals are based on customer data and deviations could result in an incorrect result. Once hydration of the pellet is complete, perform your analysis immediately. Waiting more than 30 minutes to perform your analysis could have an effect on results. Gently shake the sample prior to taking aliquots for analysis.

Culture Media: Quality of culture media is critical. Never prepare media from raw ingredients if a source of dehydrated media is available. If preparing dehydrated media, follow instructions closely. Always check pH and make any adjustments that are necessary. Always evaluate media prior to first use. Never use media outside of its expiration date and never use media that has not been stored according to the manufacturer’s specifications. Confirm that prepared media and dehydrated media ingredients and proportions match the specifications for your method.

Dilution and Rinse Water: Only hydrate the gelatin tablet using the phosphate buffer supplied by Waters ERA. To perform dilutions and apparatus rinsing, do not use deionized water or distilled water. Waters ERA recommends phosphate buffer or peptone water as it is not uncommon for deionized water or distilled water to cause inhibitory effects. See Standard Methods 9050C 20th Edition for the preparation of buffered water or peptone water.

Order DMR-QA Products